- Products

- Impact & abrasion protection

- Bend & fatigue protection

- Buoyancy & floats

- Downhole protection

- Guides & clamps

- Seabed stability

- Sensors & monitoring

- Sectors

- About us

- Knowledge

- News

- Careers

- Contact

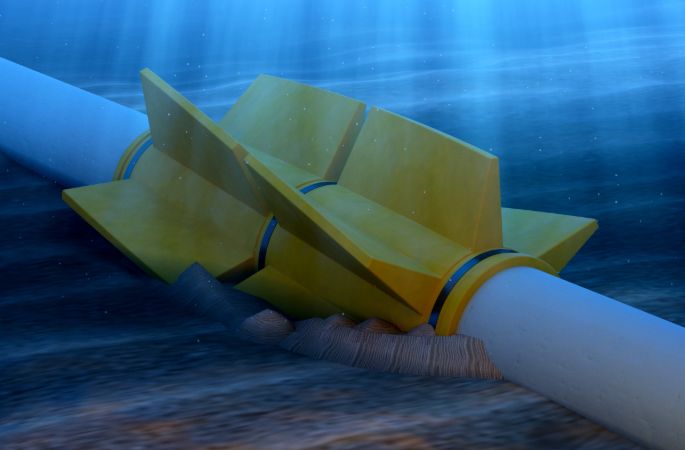

Subsea cables, umbilicals and flowlines laid on the seabed without trenching commonly suffer from motion instability. This can be externally induced by current flow, internally induced by thermal variations or slugging, can be due to bathymetric features (seabed geometry) or the laid characteristics of the flowline. This motion instability can sometimes be referred to as on-bottom stability, axial walking or lateral sliding. Irrespective of the phenomenon causing the motion instability, the system should be controlled in its movement, remaining in its laid location where desired or allowed to move where needed throughout life, mitigating the risk of damage or undue stresses to cables, umbilicals or flowlines.

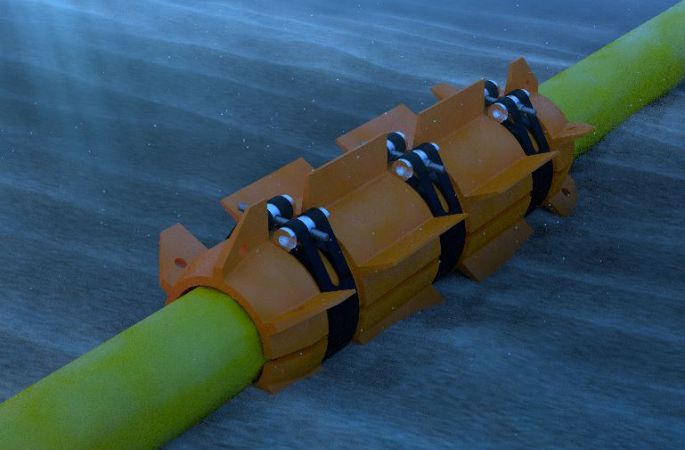

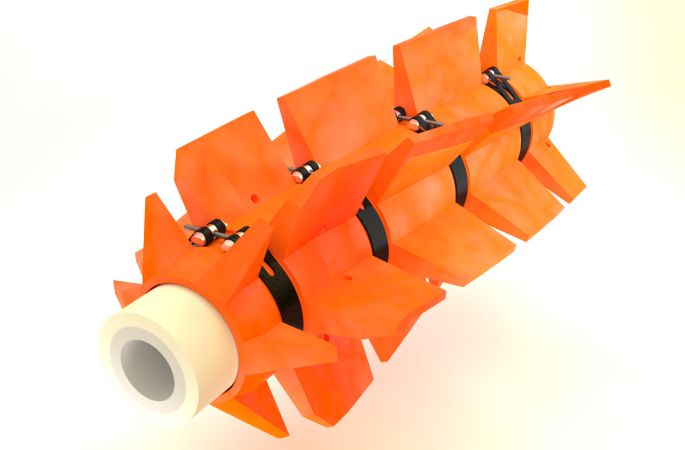

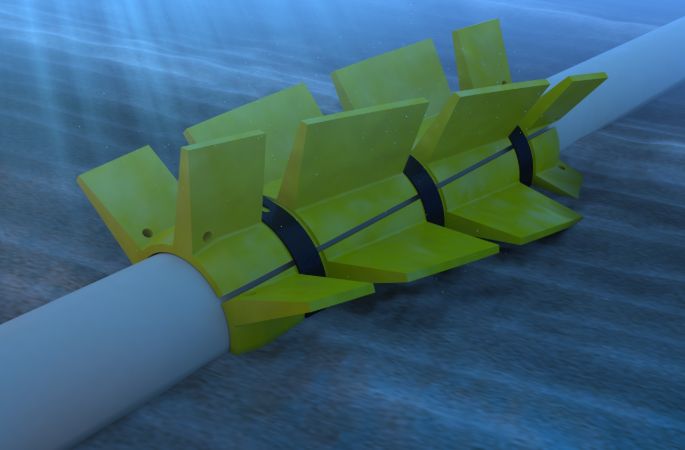

The Motion Stabiliser technology has been engineered to protect subsea cables, umbilicals and flowlines by mitigating instability in both axial and lateral directions. The unique Motion Stabiliser design includes self-burying helical fins of varied pitch along the length of the stabiliser, that anchor into the seabed increasing overall resistance by over three times. The fins are custom designed for the varied soil conditions, to ensure they effectively embed into the seabed and create the required resistance per meter of the system.

Motion Stabilisers use established Uraduct® and Tri-strakes® materials and designs, supplied in two lightweight halves, which are quickly and easily banded together in minimal time during pipe lay deployment operations, without the need for a secondary vessel. The Motion Stabiliser is resilient and will survive considerable seabed abrasion and overboarding chutes or S-Lay operations.

Motion Stabilisers are manufactured from CRP Subsea’s highly abrasion resistant API 17L certified Uraduct® material, with an enviable track record of over 30 years, used in a variety of locations and environments.

Motion Stabiliser powered by Mimir Digital Intelligence

The Motion Stabiliser can be customised to be powered by Mimir Digital Intelligence, providing you with continuous monitoring and recording of cable, umbilical and flowline motion data. This includes a built-in Digital Intelligence electronic module, encompassing a state-of-the-art multi-sensor array, providing an effective solution for continual monitoring without the need for additional stand-alone monitoring devices.

Custom designed to specific field and project requirements

Mitigates pipeline and cable instability in both axial and lateral directions

Excellent abrasion resistance

Protects pipelines and cables from damage

Fully validated with micro, medium and full-scale custom test rigs, bespoke measurement equipment and testing procedures, replicating exact seabed conditions during validation activities

Lightweight, quick, easy and safe to install

Mates to the flowline rather than covering, increasing reliability

API 17L certified material

REACH compliant material - Hg (Mercury) free

Can be tailored to fit any size pipeline or cable

Customisable to be powered by Digital Intelligence

Remove the need for secondary stability operations

Reduces the need for anchors, piles or tether clamps

Reduces the risk associated with working above subsea structures

Seabed stability

Control of flowline dynamic spans

Control of flowline curvature

Supports reduction of risk of touch down point (TDP) inflexion

Prevents buckling zone feed in

Alternative to concrete mattresses and cast-iron ballast

Subsea pipelines and cables

High temperature high pressure pipelines

Challenging seabed environments

Ultra-deep-water environments